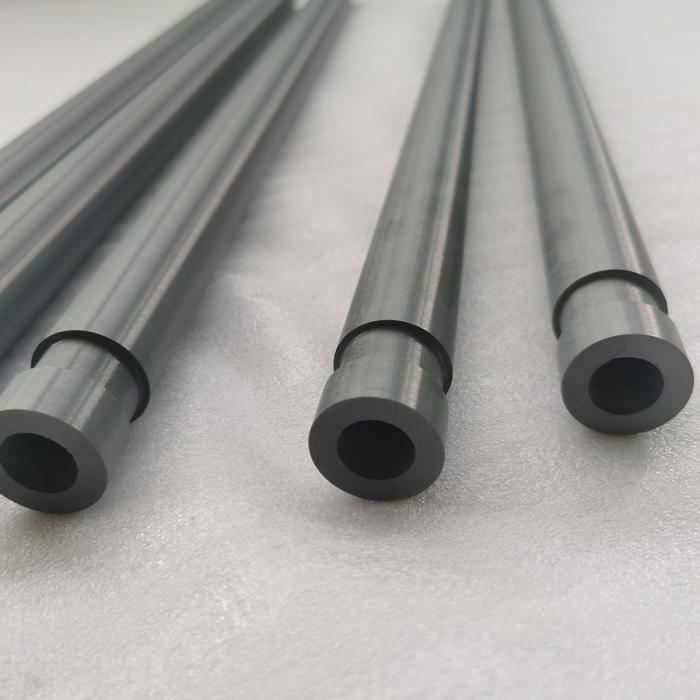

The advantage of Integrated tube alumina ceramic tube

火力发电厂输煤系统输送原煤,运行过程中,原煤会对设备造成较大冲击。因此,不能采用陶瓷片,否则,运行中将会出现大面积脱落。The coal will bring great impact to the equipment during transportation in the coal handling system of power station,so the alumina ceramic tiles is not available and they will fall off by large area.

脱硫系统中需要用到阀门,阀门在开/关过程中,改变了物料的流向,夹杂着颗粒的高速浆体会很快将阀门两端直管磨穿。因为管道内液体含有较多的亚硫酸根,具有较强的腐蚀性,为避免腐蚀,一般采用非金属管道,如橡胶管、PVC管等。但这些管道抗磨性能非常差,就会出现阀门两端直管经常被磨穿的现象。为了解决这个问题,需要寻找一种既耐磨损又耐腐蚀的产品。一体成型耐磨陶瓷管道应运而生,可以很好地解决这个问题。The valve in the desulfurization system can change the follow during the switching process, so the slurry with grain at high speed will wear out the pipe at the ends of valves. The liquid in the tube contains much sulfite which is very corrosive, so usually nonmetallic pipes like rubber tubes and pvc pipes are used to avoid corrosion, but the wear resistance of these tubes are poor that the straight pipe at the ends of valves always worn out. The integrated pipes which resist abrasion and corrosion are developed to well solve the problems of abrasion

由于内衬陶瓷管为一体成型,浆体就不可能渗透,同时陶瓷管具有很高的硬度,等静压干粉成型的工艺对陶瓷晶体结构的均一性非常有利,因此在耐磨性能方面优于同等材质的瓷片。

Because the lined ceramic tube is one piece, the slurry could n’t permeate through it, moreover, the ceramic tube has high hardness and the process by isostatic pressing dry powder is favorable to the uniformity of ceramic crystal structure, so the its wear resistance is better than ceramic tile’s with the same material.

陶瓷管道在物料输送过程中,其最薄弱的位置就在于陶瓷与陶瓷之间的衔接部位,物料颗粒对其磨损的同时,冲击作用非常关键,这也是贴片式陶瓷管道易磨损易脱落的主要原因。

The weakest place is the gap between each sticked tiles during material handling. The material grains not only wear the pipe but also have impact on it. This is why the pipelines lined by tiles are easily worn out and fallen off.

实验证明,相同厚度的陶瓷管与陶瓷片比较,使用寿命至少可以提高五倍。The experiment shows that the service life of ceramic tube is at least 5 times longer than ceramic tiles of the same thickness.